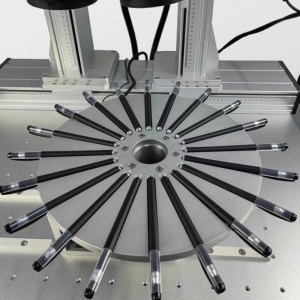

I-Ceramic Core

Okokuqala, kunxibe ngokuchasene nokunganyangeki kwaye kunokusebenza kakuhle ngexesha lokusetyenziswa kwexesha elide. Akuthambi ukunxiba kunye nokudakumba, ukwandisa kakhulu inkonzo yobomi bemveliso.

Ukunganyangeki kwe-corosions yayo entle kwenza ukuba isebenze ngokuthobeka kwiindawo ezahlukeneyo ezinobunzima ngaphandle kokuba zikhutshiwe ngezinto zekhemikhali, ziqinisekisa ukuthembeka kwemveliso.

Uzinzo lwe-shirmal ye-ceramic ilunge kakhulu. Nokuba kubushushu obuphezulu okanye indawo obunamagumbi obushushu aphantsi, inokugcina uzinzo lobungakanani kunye nokungqinelana kwentsebenzo, kwaye ukusebenza kwentsebenzo akuyi kuchaphazeleka kukutshintsha kobushushu.

Ngaphaya koko, iyodwa yokucoca ukungcola, inokungcolisa ngokufanelekileyo ukungcola, ukubonelela ngothutho olunyulu, kwaye ifezekise iimfuno zokuchaneka okuphezulu.

Ngapha koko, umphezulu we-ceramic core igudileyo, engathambeki ekukhuleni kwentsholongwane kunye nokuqokelelwa komdaka, kwaye kulula ukucoca nokugcina, umgudu.

Ukuqukumbela, isiseko se-ceramic kukuzisela amava afanelekileyo kwaye asezantsi asebenzisa iimpawu zayo zokungaxhathisi, ukuxhathisa i-corosion, uzinzo lobuqhetseba, ukucocwa okuqinisekileyo kunye nokucoca ngokuchanekileyo.