Ukuvelisa imveliso yemveliso yanamhlanje, inkqubela phambili yetekhnoloji ye-ilding ibaluleke kakhulu. Njengetekhnoloji evelayo, umatshini we-Welfeld Laser Welling uguqula amashishini amaninzi.

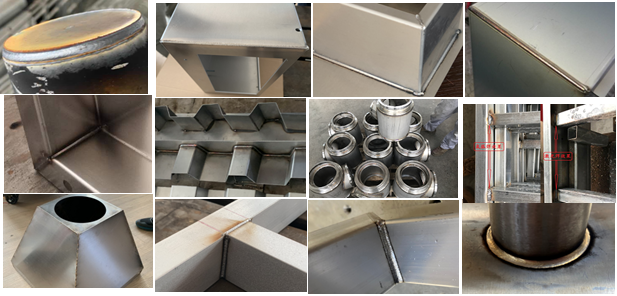

Umatshini we-Laser Welding we-Welding unezibonelelo ezibonakalayo. Kulula ukusebenza. Abasebenzi banokuyisebenzisa emva koqeqesho olulula, ukunciphisa ukuxhomekeka kubasebenzi abanezakhono. Umthungo we-WOD Muhle kwaye ugudileyo, ngaphandle kwesidingo sokugaya okulandelayo, ukugcina iiyure kunye neendleko.

Iiparamitha zayo eziqhelekileyo zobugcisa kunye nezalathi zentsebenzo zibandakanya: Amandla e-laser kuhlala phakathi kwe-1000w ne-2000w, kwaye unokukhethwa njengoko kufuneka; I-Laser ye-Laser ye-Laser yi-1064nm; Isantya se-welding sinokufikelela kwiimitha ezininzi ngomzuzu; Ukungena kwe-Wood Seam kunokulungiswa; Umda wobushushu mncinci kakhulu.

Kumzi-mveliso wemoto, omabini icandelo le-welding kunye nokulungiswa komzimba kunokusetyenziswa. Umzekelo, kwisakhelo selifayili, sinokulawula ngokuchanekileyo umthungo we-Wold kwaye uphucule uzinzo lwesakhelo. Impendulo yokulungisa i-procerir nkosi ukuba ukulungiswa komzimba kuyakhawuleza kwaye umkhondo awucacanga.

Kwintsimi ye-aerospace, i-welding yamacandelo okwakha inqwelo moya kunye nezinto ze-injini zineemfuno eziphezulu kakhulu. Umatshini we-Laser we-Laser Welting unokufumana izixhobo eziphakamileyo ze-Supeld, qinisekisa ukuthembeka kwezakhiwo zenqwelomoya, kwaye uphucule intsebenzo kunye nexesha lokuphila kwenjini. Iingxelo ezichaphazelekayo zibonisa ukuba emva kokuthatha le teknoloji, ireyithi yokufaneleka ye-welding ye-injini inyuke kakhulu.

Kumzi-mveliso we-Hardware, zombini i-welding yeemveliso ze-Hardware kunye nokulungiswa kwezinto zokubumba zisebenzise. Umntu ophethe umzi-mveliso weemveliso zeheshrewa uthe umgangatho wemveliso waqatshelwa kwaye iiodolo zinyukile.

Kwishishini lezixhobo, xa imveliso kunye nokulungisa izixhobo, kungazalisa ngokukhawuleza i-welding ukuqinisekisa amandla kunye nokuqina.

Kumzi-mveliso wesixhobo, i-welding yezindlu zokusebenza kunye nezinto zangaphakathi zixhomekeke ekwimo yayo engenamthungo, ebaluleke kakhulu, kunye neempawu zobushushu obuchaphazelekayo.

Ingxelo yabasebenzisi ilungile. Injineli kwishishini le-aerospace latsho ukuba lenze ukutsiba kwi-welding yezinto zenqwelomoya, kunye nokuxinana kwamandla. Iingcali kwicandelo lezixhobo ezivelela ukugcinwa kwexesha kunye neendleko.

Ukuqukumbela, umatshini wase-Laser Welding Welling unezinto eziluncedo kokusebenza ngokulula, amathungo amahle e-WAND, kunye neendleko eziphantsi. Inamachaphaza ngokubanzi kwimihlaba enjengeemoto, i-aerospace, izixhobo, izixhobo, izixhobo, kwaye ziya kuzisa izisombululo eziphezulu eziphezulu ze-welding.

I-Post Ixesha: Jun-29 ukuya ku-2024