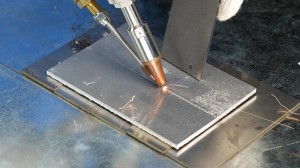

Kwimveliso yanamhlanje, isicelo seI-2000w fiber i-fiber yelling weldinesIintsimbi ze-Aluminium ze-Aluminium ziye ziya kusinda ngakumbi. Nangona kunjalo, ukuqinisekisa umgangatho wokhuseleko kunye nokhuseleko, le micimbi iphambili kufuneka iqatshelwe.

1. Unyango lomphezulu ngaphambi kwe-welding

Ifilimu yeside kumphezulu wensimbi ye-aluminium inokuchaphazela kakhulu umgangatho we-welding. Unyango olucokisekileyo lomhlaba kufuneka lwenziwe ukuze lususe ifilimu yesidi-filimu, amabala e-oyile kunye nokunye ukungcola. Xa ishishini elithile lamashishini lalivalela isakhelo se-Aluminium, ngenxa yokungakhathalelwa konyango, inani elikhulu leepores kunye namaxabiso avela kwi-SID, kwaye iqondo lokulinganisa liye laphuma kabukhali. Emva kokuphucula inkqubo yonyango, ireyithi yemfundo inyuka ngaphezulu kwe-95%.

2. Ukukhetha iiparamitha ezifanelekileyo

Iiparamitha ze-welding ezifana ne-laser yamandla, isantya se-welding kunye nesikhundla ekugxilwe kuzo sibaluleke kakhulu. Kwipleyiti ye-aluminium enobunzima be-2 ukuya kwi-3mm, amandla e-1500-1800w ifanelekile ngakumbi; Kwabo banobunzima be-3 ukuya kwi-5mm, ngo-1800 ukuya kwi-2000w efanelekileyo. Isantya se-welding kufuneka silingane namandla. Umzekelo, xa amandla aneminyaka eli-1800w, isantya esi-5 ukuya kwe-7mmmm. Isikhundla ekugxilwe kuzo sichaphazela isiphumo seWeld. Ugxininiso lweepleyiti ezincinci zisemphezulu, ngelixa iipleyiti ezinkulu, kufuneka zinzulu ngaphakathi.

3. Ukulawulwa kwegalelo lobushushu

I-Alweminium Sonst inomgangatho ophezulu wokuqhubela phambili kwaye ixhaphakile kwilahleko yobushushu, echaphazela ukungena kwe-Wold kunye namandla. Ulawulo oluchanekileyo lwegalelo lobushushu luyafuneka. Umzekelo, xa i-Aerospace Enterprise I-Aluminium I-Aluminium I-Aluminium I-Aluminium, igalelo elingelulo lobushushu elikhokelela ekufundiseni okungaphelelanga kwe-shld. Ingxaki yaconjululwa emva kokuba ingenele inkqubo.

4. Ukusetyenziswa kwegesi yokukhusela

Irhasi ekhuselweyo efanelekileyo inokuthintela i-WOLDOOD kunye ne-surusity. UArgon, i-Helheum okanye umxube wabo isetyenziswa rhoqo, kwaye inqanaba lokuhamba kunye nesikhokelo sokuvuthelwa kufuneka silungiswe ngokufanelekileyo. Uphando lubonisa ukuba inqanaba lokuhamba kwe-argon le-15 ukuya kwe-20 l / imiz kunye nolwando olufanelekileyo lokuvuthuza lunokunciphisa ukutyeba.

Kwixa elizayo, kulindeleke ukuba izixhobo ze-selser ze-selser ze-selting ze-willing ze-laser ziya kuphuma, kwaye iinkqubo ezintsha ze-welding kunye nezixhobo ziya kukhuthaza iziphumo zazo ngokubanzi. Ukuqukumbela, kuphela ngokulandela olu lwakhiwo kukhuseleko, ukuqokelela amava kunye nokwenza izibonelelo ze-lared zelding zinikezelwe ukufaka igalelo kuphuhliso lwemveliso yokwenza imveliso.

Ixesha lokuphumla: Jul-12 ukuya ku-524