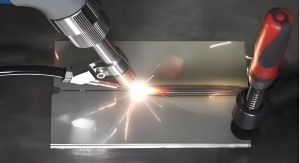

Kwintsimi yemveliso yanamhlanje yoMveliso,Umoya opholileyo opholileyo we-lelling weldingiba yinto ethandwayo yokwenyani ye-Woring yeWelding ngentsebenzo yayo ebalaseleyo kunye neenzuzo ezibalulekileyo. Ke, zithini izinto zayo ezimangalisayo? Makhe siphonononge.

I. Iiparamitha ezizobuchwephesha zibonisa ukusebenza okuqinileyo

- Amandla ase-lase-laser: Uluhlu lwamandla aqhelekileyo luphakathi kwe-800W-2000w, elinokuhlangabezana neemfuno ze-welding ze-welding ye-welding ephezulu.

- Isantya se-welding: Isantya sayo se-welding sinokufikelela kwi-5m / min-10m / imiz / imiz, ephucula kakhulu ukusebenza kwemveliso kwaye inqamleze umjikelo wemveliso.

- Ububanzi bendawo: Ububanzi bendawo iphakathi kwe-0.2mm - 2mm. Ulawulo lwendawo oluchanekileyo lunokufumana amanqaku amahle kunye aqinileyo.

- Ukusebenza rhoqo: Ukusebenza rhoqo kwe-20khz - 50kz. Umsebenzi we-Right-free qinisekisa ukuqhubeka kunye nokuzinza kwenkqubo ye-welding.

- Isixhobo sezixhobo

- Ubungakanani beenkcukacha: Uyilo lwe-Compact kunye nobude be-50cm - i-80cm, ububanzi be-30cm - i-50cm, kunye nobude obuyi-40cm, i-60cm ayithathi indawo eninzi kwaye ilungele ukucwangciswa kwiindawo ezahlukeneyo zokusebenza.

- Iimfuneko zokufaka amandla: Ngokwesiqhelo, ixhasa igalelo lamandla kwi-220v okanye i-380v, uqhelisela uluhlu olubanzi lweendawo zokubonelela ngamashishini ahlukeneyo.

- Uluhlu olusebenzayo lwezixhobo ze-welding: ilungele izixhobo ezahlukeneyo zentsimbi ezinjengeentsimbi ezingenasitali, i-carbon steen, ialuminium alloy, kunye nobhedu, ukubonelela ngamathuba okusebenza okubanzi kumashishini ahlukeneyo.

- Idatha yokusetyenziswa kwamandla e-Internetion: Ithelekiswa nezixhobo zeWolding zeSintu, ukusetyenziswa kwamanani amandla kuncitshisiwe kakhulu, kwaye kunokugcina iindleko ezininzi zamandla kumashishini ngexesha lokusebenza kwexesha elide.

II. Isixhobo esinamandla sokuphucula ukusebenza kakuhle komsebenzi

IUmoya opholileyo opholileyo we-lelling weldingUphucule kakhulu ukusebenza komsebenzi ngokusebenza kwayo. Umzekelo, kwiinxalenye ze-AutoMototive Imveliso yemveliso, kuthatha iiyure ezininzi ukugqiba i-zungung yenxalenye yeendlela ezinzima zeendlela zeWold. Nangona kunjalo, emva kokwamkela umatshini opholileyo we-welling we-selling welding, ixesha le-welding linqumla kwishumi lemizuzu. Isantya seWolding Special kunye nomgangatho wokucamngca okuphezulu kwe-welding kuye kwandise kakhulu inqanaba lokupasa ixesha elinye kwaye lanciphisa ixesha kunye nezixhobo ezichithwayo ngenxa yokusebenza.

III. Ukunciphisa kakhulu iindleko

- I-NIWS YOKUGQIBELA Ixabiso lokusetyenziswa, itekhnoloji ye-laser efanelekileyo kunye nenkqubo yolawulo lwamandla olawulo lwendlela yokuphumla ye-Laser ye-Laser ye-Laser ye-Laser ye-Laser inamandla osetyenziso lwamandla ngexesha lokusebenza, kunye nokusetyenziswa kwexesha elide kunokugcina iindleko zombane.

- Ngokwexabiso lezinto ezibonakalayo, ulawulo lwe-uplling oluchanekileyo luyanciphisa ukulahleka okwenyama ngexesha lenkqubo ye-welding, kuphucula ukusetyenziswa kwezixhobo, kwaye kunciphisa iindleko zokuthenga izinto ezingafunekiyo.

- Iindleko zokugcina zincitshiswa kakhulu. Ukusebenza kwayo izinzile kunye nolwakhiwo olulula kunciphisa i-frequency kunye neendleko zezixhobo zokusilela kunye nokugcinwa.

Iv. Ukulula okungafunekiyo ekusebenzeni

- Uyilo lokubonakala kwezixhobo luyinto e-Ergonomic, isibambo siziva sikhululekile, kwaye akukho lula ukuba sikhathazeke ngexesha lokusebenza kwexesha elide.

- Ujongano lomsebenzi wekhompyuter olulula lulula kwaye luziimvakalelo, kwaye amaqhosha okusebenza acace kwaye kulula ukuyiqonda, ukuvumela abaqhubi ukuba baqalise ngokukhawuleza.

- Umsebenzi wokutshekisha okrelekrele wenza ukuba abaqhubi benze abaqhubi ukuba bahlengahlengise iiparameter ze-welding ngokwemisebenzi eyahlukeneyo ye-welding.

Ukuqukumbela, iUmoya opholileyo opholileyo we-lelling weldingUbonakalise izibonelelo ezibalulekileyo kwicandelo le-waling ye-welding kunye neenkcazo zalo ezinamandla zobugcisa, ukusebenza kweendleko ezibonakalayo, iindlela ezisebenzayo zomsebenzi. Nokuba kukuphucula ukusebenza kwemveliso, ukunciphisa iindleko zemveliso, okanye unike amava okusebenza ngokufanelekileyo, lukhetho olufanelekileyo. Kukholelwa ukuba kwixa elizayo, iya kudlala indima ebalulekileyo kwimimandla emininzi kunye nokukhuthaza ukuphuculwa okuqhubekayo kwemveliso yemveliso.

IXESHA LOKUQALA: UJUL-09-2024